An environmentally sensitive brewery that makes more beer out of less water while using less energy has commenced production in the home of one of the world’s leading beer drinking countries, Australia.

Pacific Beverages’ new Bluetongue Brewery in New South Wales features a state-of-the-art water recovery plant, which targets best-practice water reuse standards. The water recovery plant also provides renewable energy for the brewery, reducing its dependence on fossil fuels.

The system – which was designed as a model for food and beverage plants globally – was installed by a partnership of CST Wastewater Solutions and Global Water Engineering (GWE), which are respectively Australian and global leaders in environmental engineering.

The $120 million state-of-the-art Bluetongue Brewery on NSW’s Central Coast will eventually have an annual capacity of 150 million litres, producing premium beers for increasingly discriminating palates in a nation with the world’s fourth-largest annual per capita beer consumption, 109.9 litres. (Behind only the Czech Republic, Ireland and Germany).

Pacific Beverages – a joint venture by Coca-Cola Amatil and global brewer SABMiller – has ensured the brewery will boast strict environmental standards and world-class water and energy savings, says the CEO of Pacific Beverages Mr Peter McLoughlin.

“Bluetongue Brewery is designed in a modular format which allows it to grow as we do. Coupled with this flexibility are significant sustainability credentials, predominately water and energy. Using water recovery techniques and modern design principles, we are able to target a reduction in our water usage to 2.2l / l litres of beer produced, which is amongst the best in the world and certainly well above the global average of 4 – 5 litres of water to every one litre of beer.

“Methane from this process will also power a third boiler which will reduce our energy consumption by about 15 per cent” Mr McLoughlin told the first taste launch event.

Bluetongue Brewery’s water recovery is subjected to GWE’s state-of-the-art anaerobic treatment that significantly reduces the brewery’s carbon footprint by avoiding the release of carbon dioxide into the atmosphere, say CST Wastewater Solutions Managing Director Mr Michael Bambridge and GWE CEO Jean Pierre Ombregt.

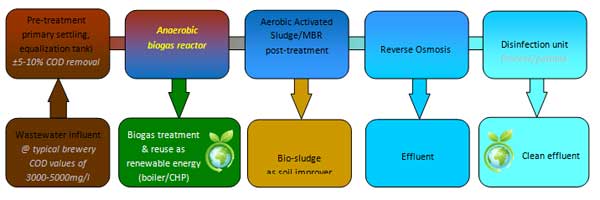

The wastewater passes through several pre-treatment steps before entering a GWE ANUBIX-B anaerobic methane reactor in which the wastewater’s organic content (COD) is digested by bacteria in a closed reactor, degrading the compounds and converting them into valuable biogas and cleaned effluent.

Biogas from the process is collected and reused as renewable energy to power the brewery’s boiler.

Treated effluent continues to an aerobic post-treatment stage in which organic content is further reduced by GWE’s proprietary MEMBROX Membrane Biological Reactor (MBR) system.

In the water polishing step, the water from the MBR unit is sent through a Reverse Osmosis (RO) installation. Finally the effluent is led to a disinfection and storage unit, where the recycled water is kept for reuse applications.