As resources and infrastructure companies pause during the traditional Christmas New Year maintenance season to consider their technology needs for the year ahead, many will need to focus on environmentally effective wastewater treatment systems for sites that can be remote or in challenging physical environments.

Increasingly stringent regulatory requirements mean that not only do companies need to ensure their discharges are treated to high quality standards, but also that wherever possible water is recycled to make best use of this precious shared community resource.

Reliability and low maintenance are essential in such applications, which is where the latest Smith and Loveless TITAN MBR QUBE® and proven FAST® wastewater treatment systems installed in Australia by CST Wastewater Solutions build on an outstanding record encompassing diverse infrastructure, construction, oil and gas and mine sites.

One of the Australia’s first FAST® (Fixed Activated Sludge Treatment) plant was installed more than 30 years ago at Xstrata’s Tahmoor Mine in NSW, where it is still successfully treating effluent to high discharge standards.

“We also have units in the Bowen Basin of Queensland that have been in service for 20-30 years, while many more similarly compact S and L FAST® units are giving excellent service in Australia and globally,” says CST Wastewater Solutions Managing Director Mr Michael Bambridge.

The latest Smith and Loveless MBR (membrane biological reactor) wastewater treatment system, the TITAN MBR QUBE™, provides a simply installed, low maintenance and environmentally effective wastewater treatment system suitable for remote resources, construction and tourism sites

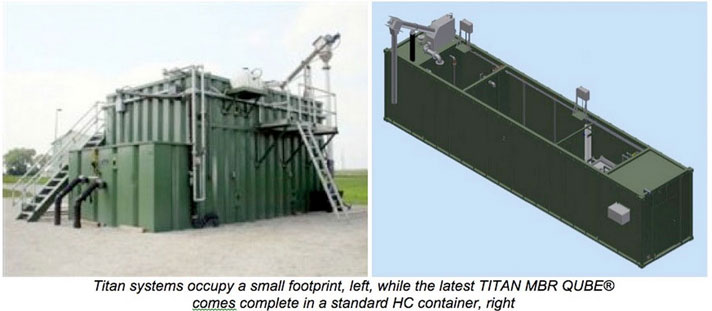

It comes complete in a standard HC (40-foot High Cube) container, completely factory pre-assembled, packaged and delivered. The plug-and-play unit needs only a flat pad to sit on and connections to water and electricity. This robust and efficient low-maintenance system is proven in diverse industrial and municipal applications where strong environmental performance is mandatory.

Titan MBR QUBE marries the 65-plus years of wastewater treatment engineering expertise of Smith & Loveless with submerged flat-plate membrane technology that ensures high permeability and flux rates.

Performance combination

This combination yields a dynamic MBR system that provides end-users with high quality treatment performance coupled with minimal operational requirements for applications involving flows in the range of 25-100m3 a day (depending on BOD, biochemical oxygen demand, and whether nitrogen removal is required).

TITAN MBR QUBE’s flat-plate membrane design results in less wear and tear than hollow-fibre types and can easily be cleaned in place. Air scouring prevents fouling and eliminates the need for back-pulsing pumping equipment.

“The technology is custom-engineered for situations such as those encountered by mining, oil and gas and remote infrastructure construction sites, which require strong ongoing protection of shared community water resources through a stand-alone system that doesn’t require complicated ongoing operating skills and knowledge,” said Mr Bambridge.

TITAN MBR™ systems come in standard and custom designs, and result in smaller footprints than conventional systems.

The submerged membrane eliminates the need for clarifiers and sand filters, and it produces significantly better effluent quality. Integral zones can be added to meet particular effluent goals, including nutrient removal, disinfection, sludge holding and post-aeration.

TITAN MBR QUBE low maintenance technology uses gravity pressure to drive water flow through its membranes. Clean water discharges into a clearwell, while blocked solids remain suspended in the aeration zone. Diffusers beneath the module scour the membranes while also providing an air supply to the bacteria.

The highly durable membrane is composed of PVDF (polyvinylidene fluoride) and non-woven polyester fabric. Vertical membrane surfaces do not touch each other during operation. The design prevents breakage experienced in other designs and produces higher flux rates over time.

Titan MBR QUBE membranes eliminate clogging problems experienced in hollow-fibre designs. Their smooth, continuous surfaces prevent the build up of solids that result from hollow fibres being bundled by stringy solids such as hair. The flat surfaces also facilitate air scouring in the aeration zone much more effectively than hollow-fibre designs.

The membranes maintain high permeability and flux rates even at peak-day rates. They stack within a fully submerged module inside the aeration zone. Chemical cleaning occurs efficiently in place – typically on a semi-annual basis – with simple chemical injection. TITAN MBR membranes are also designed to use less chemicals and equipment than other designs.

High performance Titan MBR units provide effluent quality of < 3 mg/L BOD and < 1 mg/L TSS. Turbidity is < 2 NTU. TKN is < 2 mg/L and NH3 is < 1 mg/L.

FAST® Process

Similarly reliable and low maintenance FAST® Process systems are available in factory-built or field-installed modules, providing high performance treatment in a minimal space.

The popular Modular FAST® arrangement handles smaller, variable flows generated from onsite applications, including schools, small developments, commercial and public facilities, and hospitality venues such as hotels, camps, and restaurants.

No daily operation is required and the installations provide significantly improved performance over traditional leach field and septic tank systems, especially when a nitrification/denitrification component is specified in permit or effluent requirements.

Proven in thousands of installations worldwide, FAST® consists of tankage packed with completely submerged media. The FAST® media creates a high surface area-to-volume ratio, which, combined with internal settling zones, maintains constant bacterial growth during low-flow and peak usage. This results in stable operation on a daily basis.

Plug-and-play TITAN MBR QUBE™ technology delivers simple, robust environmental performance on remote sites.

Plug-and-play TITAN MBR QUBE technology delivers simple, robust environmental performance on remote sites

A simply installed, low maintenance and environmentally effective wastewater treatment system suitable for remote resources, construction and tourism sites is being introduced to Australia by CST Wastewater Solutions.

The latest Smith and Loveless MBR (membrane biological reactor) wastewater treatment system, the TITAN MBRQUBE™, comes complete in a standard HC (40-foot High Cube) container, completely factory pre-assembled, packaged and delivered.

“This is very much a plug-and-play unit that needs only a flat pad to sit on and connections to water and electricity. It is a robust and efficient low-maintenance system proven in diverse industrial and municipal applications where strong environmental performance is mandatory,” said CST Wastewater Solutions’ Managing Director Mr Mike Bambridge.

The innovative pre-engineered Titan TITAN MBR QUBE™ developed by Smith & Loveless marries the 65 + years of wastewater treatment engineering expertise of Smith & Loveless with submerged flat-plate membrane technology that ensures high permeability and flux rates. This combination yields a dynamic MBR system that provides end-users with high quality treatment performance coupled with minimal operational requirements for applications involving flows in the range of 25-100m3 a day (depending on BOD (biochemical oxygen demand) and whether nitrogen removal is required).

TITAN MBR QUBE’s™ flat-plate membrane design results in less wear and tear than hollow-fibre types and can easily be cleaned in place. Air scouring prevents fouling and eliminates the need for back-pulsing pumping equipment.

“The technology is custom-engineered for situations such as those encountered by mining, oil and gas and remote infrastructure construction sites, which require strong ongoing protection of shared community water resources through a stand-alone system that doesn’t require complicated ongoing operating skills and knowledge,” said Mr Bambridge.

TITAN MBR QUBE™ units incorporate all wiring, piping, valves, CIP (cleaning in place) equipment, screening, air conditioning and remote view PLC operation, backed by the global resources of CST Wastewater Technology and Smith and Loveless, who has more than 50 years experience in the water and mineral industries, backed by a legacy of innovation and market leadership in pumping, treatment and filtration technologies.

TITAN MBR QUBE™ low maintenance technology uses gravity pressure to drive water flow through its membranes. Clean water discharges into a clearwell, while blocked solids remain suspended in the aeration zone. Diffusers beneath the module scour the membranes while also providing an air supply to the bacteria.

The highly durable membrane is composed of PVDF (polyvinylidene fluoride) and non-woven polyester fabric. Vertical membrane surfaces do not touch each other during operation. The design prevents breakage experienced in other designs and produces higher flux rates over time.

TITAN MBR QUBE™membranes eliminate clogging problems experienced in hollow-fibre designs. Their smooth, continuous surfaces prevent the build up of solids that result from hollow fibres being bundled by stringy solids such as hair. The flat surfaces also facilitate air scouring in the aeration zone much more effectively than hollow-fibre designs.

The membranes maintain high permeability and flux rates even at peak-day rates. They stack within a fully submerged module inside the aeration zone. Chemical cleaning occurs efficiently in place – typically on a semi-annual basis – with simple chemical injection. TITAN MBR membranes are also designed to use less chemicals and equipment than other designs.

TITAN MBR QUBE™ provides effluent quality of < 3 mg/L BOD and < 1 mg/L TSS. Turbidity is < 2 NTU. TKN is < 2 mg/L and NH3 is < 1 mg/L.

CST Wastewater Solutions has installed proven MBR systems in hundreds of Australasian installations, ranging from municipal and private developments to industrial and commercial sectors, as well as specialised marine use.

The company has been providing a broad range of industrial and municipal water and wastewater solutions for 25 years, with projects also completed in Europe, Asia, Africa and America