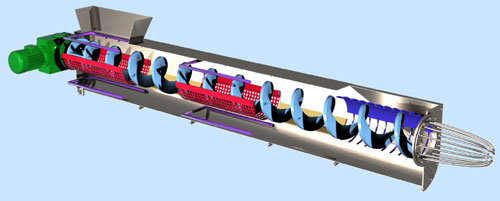

Screw Compactors

Description and Working Principle

The Screw Compactor, has combined into one unit a system for mechanical transportation, de-watering and compressing. In this way the screening volume is greatly reduced. The structural and functional simplicity of the compactor design in the form of shaftless flighting, allows for the absence of internal supports and minimum maintenance. The clever design of this equipment allows it to be used in many fields.

A sieve following the spiral end of the screw coupled with a discharge closure unit creates the dewatering and compressing action of the screenings. The liquid is pressed out through a specially designed tube. The machine is designed for intermittent working.

Performance and Technical Features

PERFORMANCE

- Throughput rates up to 8 m³/h

- Screw diameters up to 360 mm

- Depending on the type of use, volume reduction of screenings up to 40%

DESIGN FEATURES

- Trough housing made of stainless steel AISI 304

- Shaftless screw made of carbon steel or stainless steel AISI 304

- Trough liner made of UHMWP

APPLICATIONS

- Municipal waste water treatment plants for dewatering of screenings after coarse and fine screen

- Industrial waste treatment plants

- Paper mills

- Tanneries

- Chemicals

- Food processing (vegetables, fruit, fish etc.; in some cases process-integrated use)

- Others

See related links above for SDS Specification

Advantages and Innovative Features

- Absence of outlet end bearing and intermediate bearing assemblies

- No mechanical components in contact with the product handled

- Low speed

- No jamming or blocking even if with fibrous products

- Fully enclosed pollution-free and odour-free machine

- Horizontal or vertical outlet

- Possibility of discharging into plastic bags

High Performance Screenings Washer

- Increased washing

- Increased compaction