CST Wastewater Solutions packages include proven global and locally manufactured technologies ranging from fixed installations (left) to remote container or skid-mounted portable low-maintenance applications (right).

New engineer-and-build water and waste water treatment and recycling packages are being introduced by CST Wastewater Solutions for industries and municipalities that want to lower the cost and complexity of such projects.

The design, supply and install packages – incorporating global and locally manufactured technologies proven in use by some of Australia and New Zealand’s leading companies and councils – are aimed particularly at:

– Councils seeking engineering assistance to develop clear choices and optimum solutions incorporating advanced low-maintenance technologies providing high levels of water purity while reducing maintenance, waste handling and OH&S issues associated with running them.

– Industries seeking readily constructed or portable, low maintenance solutions for operations particularly in remote, ecologically or environmentally sensitive areas – ranging from resources or agribusiness developments in the country or outback, through to food, beverage, manufacturing and processing plants sharing precious water resources with urban areas.

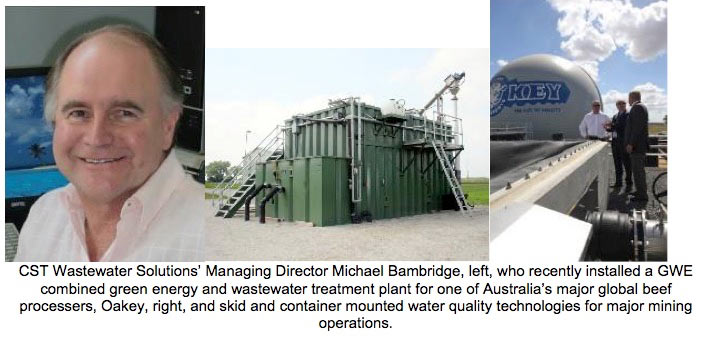

“Rather than presenting such organisations with a jigsaw of disparate collections of technologies and engineering services options for them to piece together, our packaged solutions focus on clear, properly engineered solutions that deliver what they promise. CST offers turnkey solutions based on a known raw water quality and guaranteeing water quality outcomes thus giving user engineers significant confidence in the outcomes and limiting their exposure and potential concerns,” says CST Wastewater Solutions Managing Director Mr Michael Bambridge.

“There have been major advances in water quality, water recycling and green energy from wastewater technologies over the last decade, but not all organisations have the in-house expertise these days to realise the benefits. And whereas standard solutions might have been good enough when there were fewer pressures on water quality and demand on water as a shared community resource, today water managers have to design to a much tighter and demanding sustainability brief,” he says.

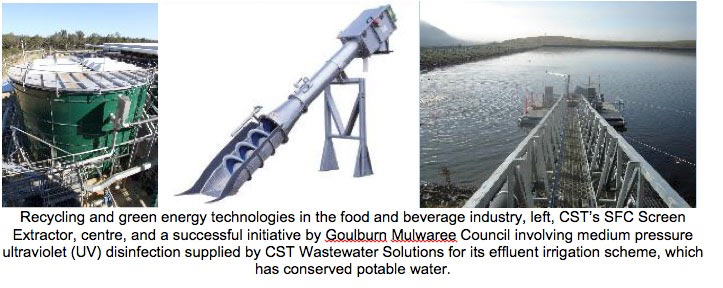

Recycling and green energy technologies in the food and beverage industry, left, CST’s SFC Screen Extractor, centre, and a successful initiative by Goulburn Mulwaree Council involving medium pressure ultraviolet (UV) disinfection supplied by CST Wastewater Solutions for its effluent irrigation scheme, which has conserved potable water.

Effective technologies are available and proven – including advanced screening, membrane and aerobic and anaerobic digestion, filtration and reverse osmosis for example – but the best combinations “just can’t be picked off the shelf to fit particular projects. They have to be engineered for local conditions or they won’t deliver on their promise,” said Mr Bambridge, whose company’s projects range from water quality plants for councils throughout Australia to green energy generation and water recycling plants for organisations such as the Bluetongue Brewery, Cadia mining, Frucor, Golden Circle and national dairy, paper and agribusiness companies.

Locally manufactured technologies – such as fine screening, for example – are already reducing maintenance and OH&S issues for Australian and New Zealand companies, while CST Wastewater Solutions also represents globally successful technologies including Smith and Loveless, Berson UV disinfection systems and Global Water Engineering water quality and green energy technologies proven in more than 300 projects worldwide. One GWE project recent won a global award from the Institution of Chemical Engineers, IChemE, which represents more than 40,000 engineers globally. GWE water quality technology – which extracts green energy from waste water to turn a problem into a profit – is currently being deployed by the leading Japanese meat processor NH Foods at Oakey Beef Exports in Queensland. The Oakey project not only radically improves waste water quality but also generates biogas (methane) to replace fossil fuels and lessen environmental impacts.

Another advanced technology, high efficiency SFC fine screening extractor technology, is currently delivering low maintenance performance with reduced OHS hazards for municipal and industrial waste water schemes. This technology, which also reduces handling of waste, is demonstrating immediate results in one of its recent applications, for the co-joined towns of Harden and Murrumburrah, where it is incorporated into the treatment system improving water quality for a population of approximately 2,000 people.

CST Wastewater Solutions’ Managing Director Michael Bambridge, left, who recently installed a GWE combined green energy and wastewater treatment plant for one of Australia’s major global beef processers, Oakey, right, and skid and container mounted water quality technologies for major mining operations.

“Many communities and industries – especially throughout regional and outback areas of Australia – face water quality and recycling issues brought about by drought and limited water resources available for drinking, agriculture, product processing and sharing between communities and their industries.

“Some such groups have limited access to the technical resources, technologies and application know-how to produce solutions to their issues, which is where packages such as we have introduced can be invaluable.”

CST Wastewater Solutions engineering team has a track record of more than 25 years successful project implementation to back its new design, supply and install packages.

For further information in Australia and New Zealand, please contact Mr Michael Bambridge, Managing Director, CST Wastewater Solutions, 16/20 Barcoo Street, Roseville 2069.Tel: 61 2 9417 3611:info@cstwastewater.com www.cstwastewater.com