Technology available in Australasia that can covert food and beverage waste water to green energy is being employed by one of the success stories of beer brewing in Latin America, Compañía Cervecera de Nicaragua (CCN).

CCN is embarking on an environmental initiative that will see it use technology from international green energy leader Global Water Engineering to harvest biogas (methane) energy from waste water to replace fossil fuels and provide reliable base load energy while simultaneously achieving much cleaner effluent.

The GWE technology involved in the latest installation at CCN is represented in Australia and New Zealand by CST Wastewater Solutions, which installed similar technology at the Bluetongue Brewery in NSW, where it is saving fossil fuel and cutting the brewery’s overall energy consumption by about 15 per cent.

CCN, founded in 1926, is Nicaragua’s biggest brewery. One of its beers – the Toña, launched in 1975 – has more than 85 per cent market share in Nicaragua and it is exported to the US. Toña has become a national symbol in its own right, featuring on its label the volcano San Cristobal and the legendary railway to the sugar mill of San Antonio. The company commenced this year the installation of a brand new GWE wastewater treatment and biogas use plant at its brewery in Managua.

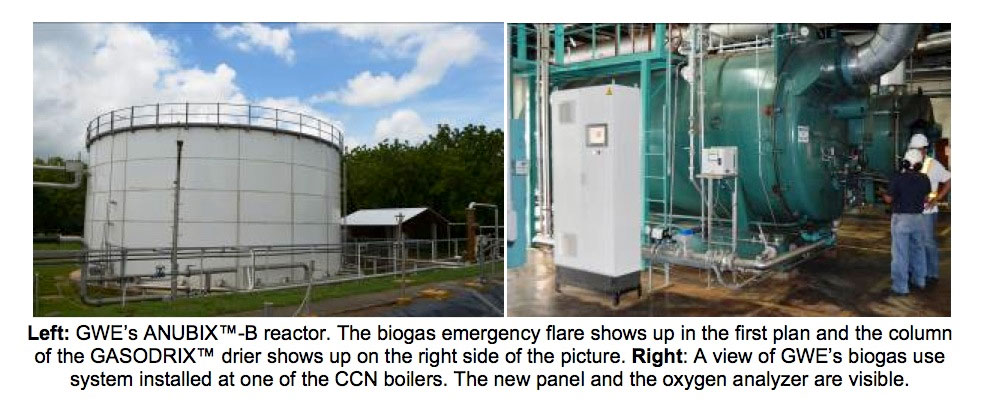

At CCN, GWE has designed and installed an anaerobic reactor incorporating ANUBIX™-B technology for 13 tons of COD throughput per day, as well as a biogas use system in one of CCN’s boilers, which allows CCN to save up to 3,000 kg of fuel oil per day. A revamp of the plant’s aerobic and a complete sludge dewatering systems have also been included in the current project.

The long distance of almost 1 km between the waste water treatment plant and the boiler room has represented an additional challenge which was successfully tackled by using GWE’s drying system, GASODRIX™. This allowed the client to use an existing pipeline at the plant without intermediate draining points. The plant is currently being commissioned for service.

CST Wastewater Solutions Managing Director, Mr Michael Bambridge, says GWE anaerobic digestion technology is applicable to a host of Australasian industries, including particularly food, beverage and agro industry applications. The technology can be used wherever industry has a biological waste stream or wastewater with high organic carbon or COD (chemical oxygen demand) of natural origin that can be broken down into biogas by anaerobic bacteria.

GWE Anaerobic technology plants can typically pay back the cost of their introduction within two years or even less –and then go on working 24/7,virtually in perpetuity, to provide biogas for their owners, who can use the energy for their own purposes, he says. The proven GWE anaerobic technology has been demonstrated in more than 300 projects completed worldwide, including more than 70 that generate biogas to replace fossil fuels in fuelling boilers and processing plant or to sellback to the electricity grid.

To assist with adoption of the technology in Australia, In Australia, CST Wastewater Solutions is partnering with national energy groups and global electricity generator suppliers to tailor Build, Own Operate and Maintain (BOOM) partnerships.

These partnerships package finance, machinery and operational expertise over agreed terms to enhance the long-term affordability of green energy projects, including those that that extract biogas (CH4) from waste water streams while simultaneously cleaning waste water to some of the highest global discharge standards.