A BOOM for business as packaged green energy solutions sweeten balance sheets and sustainability

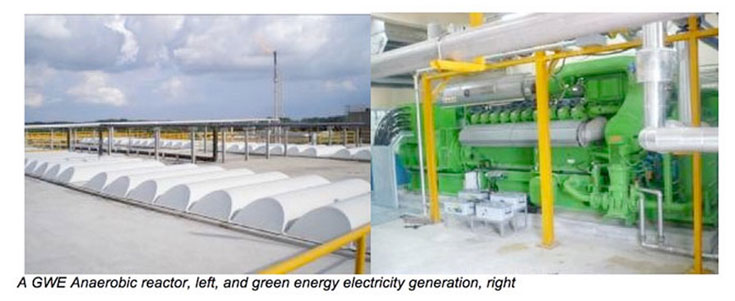

A GWE Anaerobic reactor, left, and green energy electricity generation, right

A company introducing some of the world’s most advanced green energy from waste water technologies to Australasia is forging partnerships to help companies more easily afford the most sustainable and cost-efficient solutions for their individual site’s needs.

CST Wastewater Solutions – which represents Global Water Engineering anaerobic waste water and green energy solutions in Australia – is partnering with national energy groups and global electricity generator suppliers to tailor Build, Own Operate and Maintain (BOOM) partnerships.

These partnerships package finance, machinery and operational expertise over agreed terms to enhance the long-term affordability of green energy projects, including those that that extract biogas (CH4) from waste water streams while simultaneously cleaning waste water to some of the highest global discharge standards.

The anaerobic wastewater biogas technologies – which extract methane to generate green electricity or to fuel boilers and other factory equipment – are particularly applicable to food, beverage and agribusiness companies, or any industry that has a biological waste stream or wastewater with high organic carbon or COD (chemical oxygen demand) of natural origin that can be broken down into biogas by anaerobic bacteria.

“The value of a BOOM scheme to finance and implement such installations is that the client doesn’t have to worry about the details or project risk, since they’re provided with an end-to-end service which is highly transparent in terms of pricing and service,” says CST Wastewater Solutions Managing Director Mr Michael Bambridge.

“Companies entering into such a partnership also get a really thorough review performed on their current energy efficiency and billing structure. The hard work is done for them and the risk mainly assumed by skilled and experienced partners with national and international experience in energy efficiency and electricity generation.”

Similar global expertise is embodied in the GWE anaerobic technologies of which more than 300 have been completed worldwide, including more than 70 that generate biogas to replace fossil fuels in fuelling boilers and processing plant or to sellback to the electricity grid.

GWE anaerobic technology is the Bluetongue brewery in NSW, for example, and in a Corn Products International plant which is a major global producer of native tapioca starch, sweeteners and modified starch operating in 50 countries. This plant in Thailand produces up to 70,000 Nm3 a day of biogas, corresponding to circa 43,750 kg a day of heavy fuel oil, worth $US 12.7 million ($A approx 12.2 million, 9.5 million Euro) a year. Such installations typically pay for themselves within two years, often less.

“We as the technology supplier partner with energy and machinery organisations to develop packaged integrated energy solutions using renewable biogas for onsite cogeneration or trigeneration,” says Mr Bambridge.

BOOM schemes remove operational and financial risk of biogas plants from companies interested in the financial and environmental benefits of the technology but who may not have experience in this area.

“Our energy partners, for example, are able to leverage the strengths and experience of major energy organisations that have implemented this type of scheme,” says Mr Bambridge.

“The competitively packaged solution offers the combined experience and expertise of market leaders in their own respective fields to the benefit of clients who have statutory need to treat waste water to high standards and have the profit potential to use of biogas in cogeneration facilities.

“BOOM solutions allow the client to concentrate on their core business while opening the door to proven environmental and financial benefits that provide a permanent competitive edge.”

The GWE technology deployed in Australasia by CST Wastewater solutions is proven at more than 300 food, beverage, agro industry and processing plants in more than 60 countries including Asia, Africa, North and South America, Australia, China, Europe (including Eastern Europe) and Russia.

Users of GWE technology include companies such as Budweiser, Chang, Carlsberg, Coca Cola, Corn Products Int’l, Danone, Fosters, Heineken, Interbrew, Kraft, National Starch & Chemicals, Nestlé, Pepsi Cola, SAB-Miller, San Miguel, Singha, Sunkist, Tsingtao and many more.