In Line Fine Screens For Irrigation Ballast Water, Water Re-use

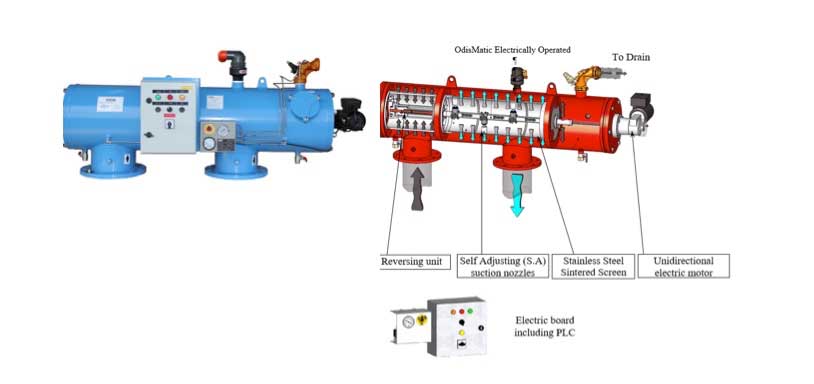

The OdisMatic® Electric Filters are an automatic self-cleaning heavy-duty electrically operated screen filters designed to treat water for drinking, industry, recycling applications and irrigation.

The filters uniqueness lies in the efficient, economical automatic self-cleaning mechanism.

It combines a Self-Adjusting (S.A-patent pending) suction nozzles driven by a unidirectional electrical motor and a reversing direction screw (S.A – patent pending) which enables a continuous linear movement (back and forth) of the cleaning mechanism.

The nozzles are self-adjusting in accordance with the screen surface. The accurate contact point between the unique S.A nozzle and the screen insures an increased suction ability and decreases significantly the water consumption during flushing. The above mechanism is designated for perfect screen cleaning. The screen cleaning process does not interrupt the filtration process

Principle of operation:

The process consists of two filtration stages:

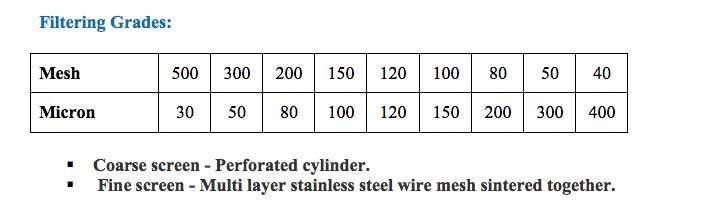

First stage – coarse filtration: the raw water enters the filter through the inlet and passes through the coarse screen to the inside of the filter. This prevents passage of large particles which may damage the filter internals.

Second stage – fine filtration: The water passes through the fine screen from inside out to the filtered water chamber and exits through the outlet. As the water passes through the fine screen, the solids accumulate creating a cake of dirt on the inner surface of the screen.

As a result the pressure drop across the screen increases, and when it reaches a pre-set level (0.5 bar. 7.5 psi) the filter controller activates the self-cleaning process.

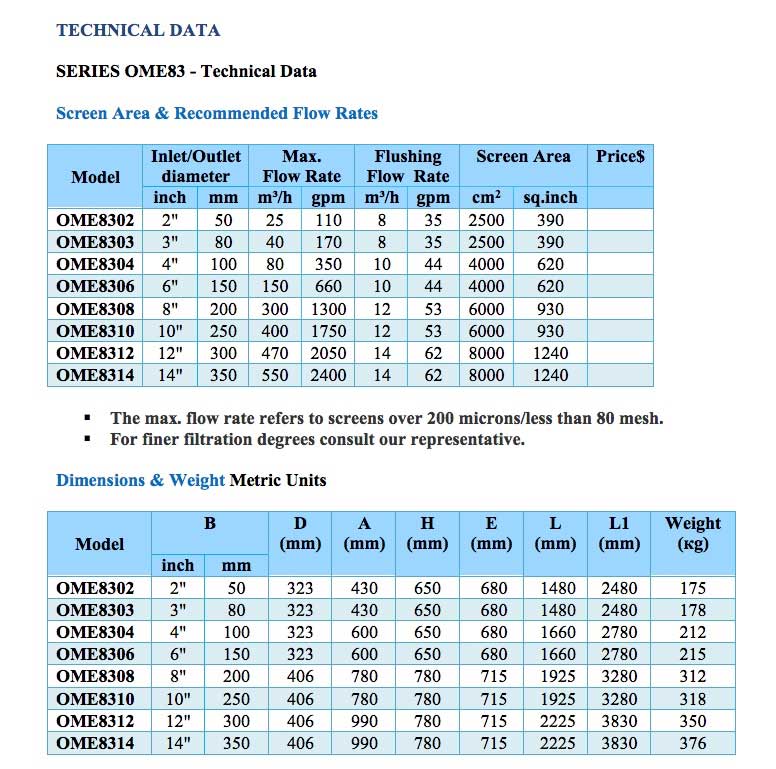

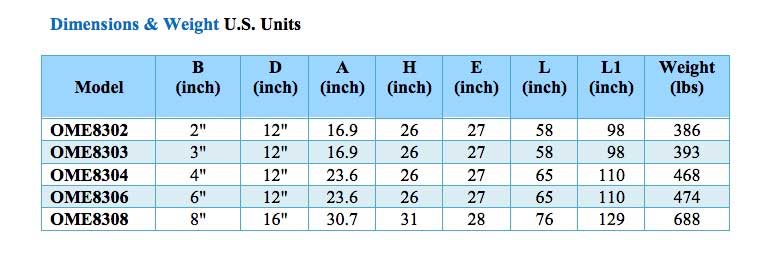

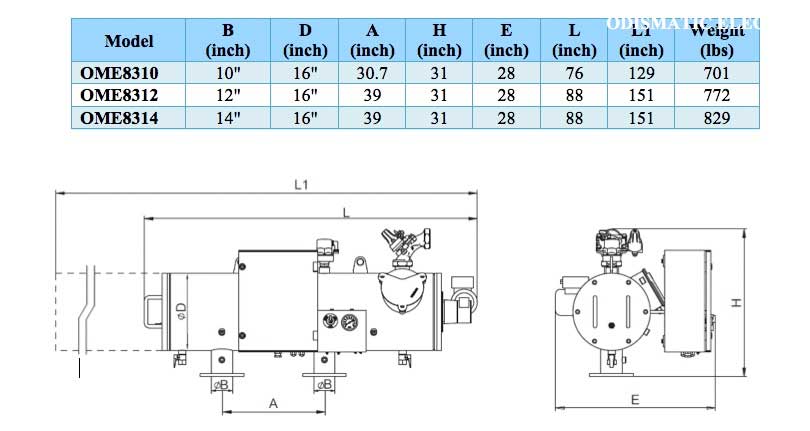

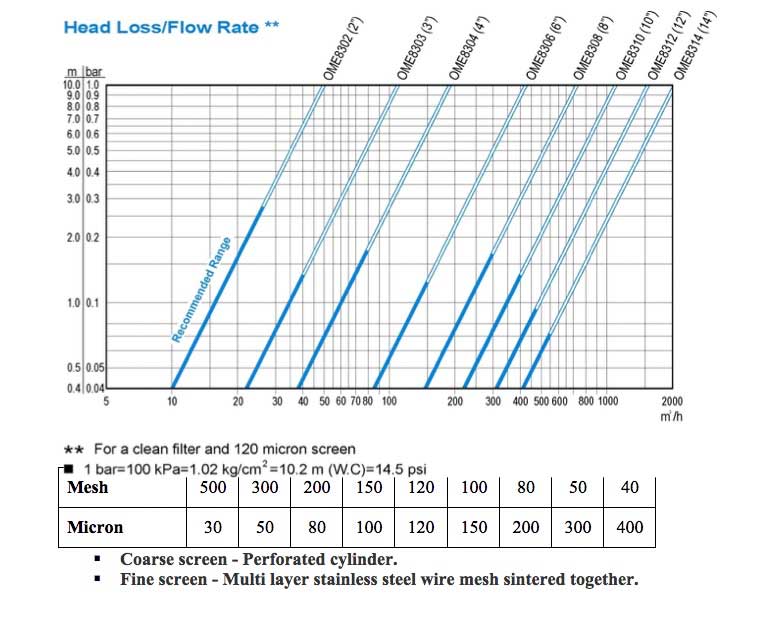

TECHNICAL DATA

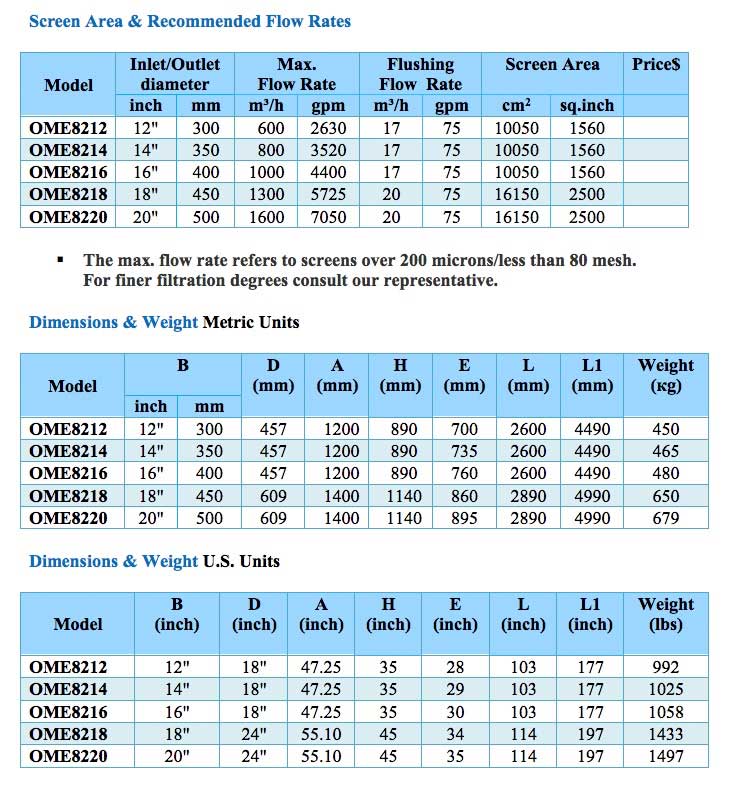

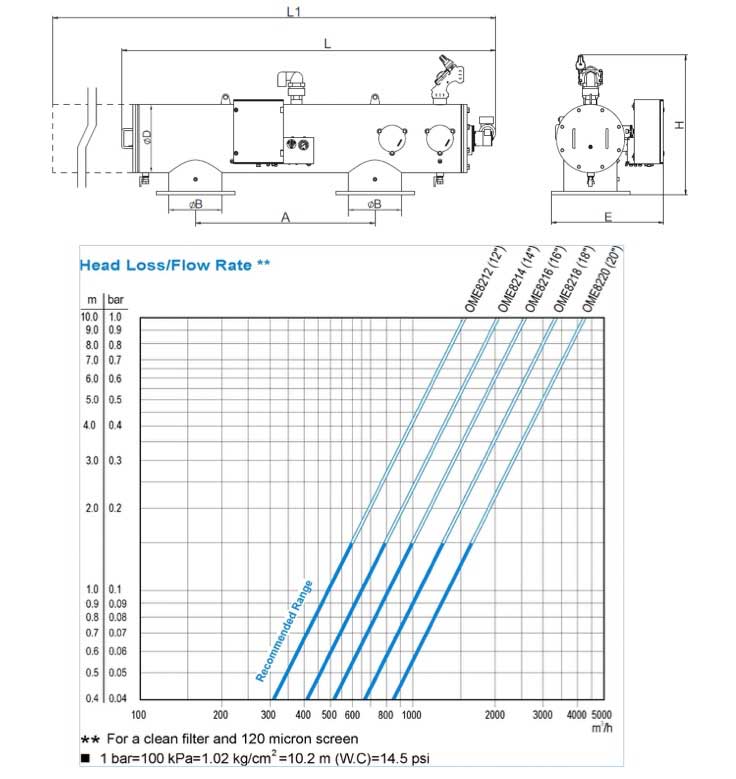

SERIES OME82 – Technical Data